-

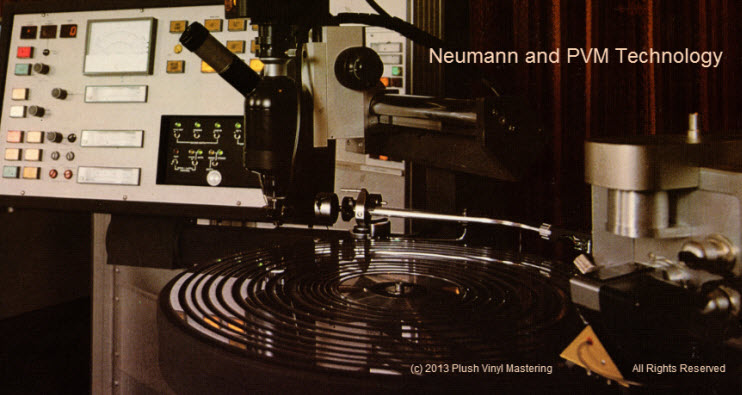

In today’s cutting realm, PVM’s patented Lacquer Master Proofing System® is the only of its kind. Lacquer Master Imaging® (LMI) another PVM development is real-time, non-physical monitoring of lacquer masters as they are cut.

The Landmark: What could previously only be known after the lacquer master is processed (to its many metal parts: Father, Mother, Stamper), and waiting several days for a vinyl test pressing. Now, we can precisely hear the lacquer master’s groove, and also capture it as an archival proof. This advance knowledge is powerful proof and the best quality control measure to ensure the lacquer master coming from Plush Vinyl is perfect. >>

The Landmark: What could previously only be known after the lacquer master is processed (to its many metal parts: Father, Mother, Stamper), and waiting several days for a vinyl test pressing. Now, we can precisely hear the lacquer master’s groove, and also capture it as an archival proof. This advance knowledge is powerful proof and the best quality control measure to ensure the lacquer master coming from Plush Vinyl is perfect. >>

Unprecedented Assurance

Unprecedented Assurance

Since the lacquer master’s groove ‘image’ is recorded and archived, it remains a positive proof, and your best ‘evidence’ of quality. Also one may simply wish to listen to the lacquer master proof. While not a replacement for the vinyl test pressing, its availability, play-ability, and convenience, unprecedented. A means of complete confidence.

LMI (Lacquer Master Imaging®)

LMI (Lacquer Master Imaging®)

The precise orchestration of multiple lasers: three for positioning (groove alignment), three for scanning. Revealing 70% more (play) area than a physical playback stylus nominally resting upon two contact points of the groove. Although different technology, LMI has much in common with Blu-Ray and DVD laser systems. LMI laser-light frequencies are ‘tuned’ for the ‘analog’ read of the lacquer master medium.